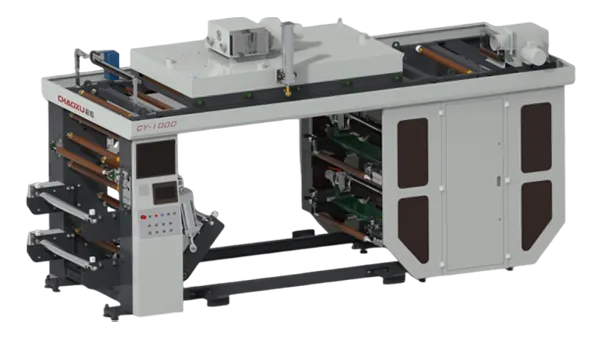

Modern slitting machines have revolutionized aluminum foil processing by combining precise cutting technology with high-speed operation. They can cut massive, delicate rolls of aluminum foil into perfectly narrow widths, minimizing manual intervention, reducing material waste by up to 15%, and increasing output by 30% or more. At the heart of this transformation? Advanced tension control, sharp blade systems, and intelligent automation. For brands like Chaoxu, it's not just about the machine itself, but about creating a seamless, customized workflow that perfectly integrates with your factory production line.

The Aluminum Foil Industry's Need for Speed and Precision

Walk into any foil packaging plant, and you’ll feel the pulse of urgency. Orders pile up, deadlines loom, and every micron of waste hurts the bottom line. Aluminum foil isn’t just tricky; it’s downright temperamental. Too much tension? You get wrinkles or tears. A dull blade? Burrs and uneven edges. I’ve watched operators spend hours tweaking settings on older machines, only to end up with inconsistent slits. The industry’s shift toward thinner, high-strength alloys for sustainability has only upped the ante. According to a 2023 report from the Aluminum Association, nearly 40% of foil manufacturers cite “slitting accuracy” as their top bottleneck. That’s where today’s slitting machinery enters—not as a mere tool, but as a game-changer.

How Slitting Machines Work Their Magic

Forget the clunky, noisy beasts of the past. Contemporary foil slitting equipment is a symphony of mechanics and microprocessors. Picture this: a massive jumbo roll of foil, maybe 2 meters wide, feeding into the machine. As it glides through, circular blades—often coated with diamond-like carbon for longevity—make contact. But here’s the kicker: they don’t just chop down. They use a “shear” or “score” method, depending on foil thickness, to create clean, sealed edges that prevent unraveling. The real hero, though, is the tension system. Using servo-driven rollers and real-time sensors, it maintains a Goldilocks-level “just right” pull throughout. No slack, no excessive strain. Chaoxu’s engineers often compare it to guiding a sheet of tissue paper through a storm without a tear. It’s that delicate.

Key Features for Enhanced Foil Slitting Efficiency

So, what separates a mediocre slitter from a powerhouse? Three things: precision, adaptability, and brains.

Precision Blade Alignment and Setup

Every millimeter counts. Modern slitter machines allow for tool-less blade adjustments. Operators can set widths via a touchscreen in seconds, swapping from 10mm strips for capacitor foil to 500mm for food packaging without breaking stride. Laser-guided alignment ensures each blade hits its mark dead-on. I’ve seen setups where manual machines took 45 minutes for changeovers; automated systems slash that to under 5 minutes. That’s more uptime, less frustration.

Advanced Tension Control for Flawless Winding

Tension is the silent saboteur. Too loose, and the foil layers slip, creating telescoped rolls. Too tight, and you stretch or tear the material. State-of-the-art slitting machines use closed-loop tension control, constantly measuring and adjusting via load cells. Some even integrate pre-programmed taper tension profiles, easing pressure as the roll diameter grows. The result? Tight, uniform rewinding that looks flawless on the pallet.

Automation and Smart Integration

This isn’t just about motors and blades. It’s about data. Imagine a machine that learns. Sensors track blade wear, vibration, and thermal expansion, predicting maintenance needs before a failure occurs. Automated slitting systems can sync with factory MES software, auto-adjusting schedules based on order priority. At a Chaoxu demo last year, I watched a line switch between three different foil grades automatically—no human touch until the labeled rolls exited. That’s the future, already here.

More Than Just Faster Cutting Speeds

Let’s talk numbers. A case study from a European converter showed that after installing a high-precision slitting line, their material utilization rate jumped from 88% to 96%. That’s 8% less scrap—a massive saving when dealing with tons of foil monthly. Speed isn’t just about linear meters per minute; it’s about consistency. Fewer defects mean fewer re-runs, less energy spent on reprocessing, and happier customers. There’s also a safety angle: automated handling reduces direct contact with blades, lowering accident rates. One plant manager told me, “It’s like going from wrestling with the foil to conducting it.”

Customization and Innovation in Perfect Harmony

Here’s where generic advice ends and real-world solutions begin. Chaoxu doesn’t sell cookie-cutter machines. They start with your pain points. Are you slitting ultra-thin 0.006mm foil for pharmaceutical blisters? Their systems come with environmental enclosures to control static and airborne dust. Working with laminated foil for insulation? They’ll tweak the web handling mechanics to prevent delamination. I recall visiting a snack food packaging plant where their old slitter left microscopic edge burrs, causing sealing issues on high-speed filling lines. Chaoxu’s team designed a custom blade-angle configuration that essentially “polished” the cut edge. Problem solved. That’s the difference—a partner who listens and adapts.

Smart Technology Overcoming Common Slitting Challenges

Even the best gear faces hurdles. Static electricity can make foil cling and misalign. Modern slitters include ionizing bars to neutralize charge. Dust and aluminum particles accumulate? Integrated vacuum systems suck debris away from the cutting zone. Then there’s the human factor: operator error. Chaoxu’s interfaces use intuitive graphics and preset “recipe” buttons for different materials. It’s like switching from a manual transmission to an intelligent cruise control—smoother, simpler, smarter.

The Future of Aluminum Foil Slitting

What’s next? I’m betting on two trends: deeper AI integration and sustainability drives. Machines will not only self-optimize but also suggest blade-life extensions or energy-saving modes based on real-time grid costs. Additionally, as foil recycling gains focus, slitters will need to handle higher percentages of post-consumer recycled content, which often behaves differently. The slitting machines of tomorrow will be predictive, not just reactive.

Conclusion

Don’t just buy a machine; invest in a solution. List your non-negotiables: maximum web width, core diameters you use, desired changeover speed. Ask for material trials—any reputable brand like Chaoxu will test-slit your actual foil. Peek behind the cabinet: is the wiring tidy? Are components from trusted suppliers? Finally, consider the software. Can it grow with your needs? A good slitter today should be upgradeable for tomorrow’s challenges.

Ready to transform your aluminum foil slitting operation? Chaoxu’s experts are here to analyze your line and recommend a tailored slitting machine solution. Contact us today for a free, no-obligation consultation and see our machines in action—because efficiency shouldn’t be a guessing game.