Examples of errors resulting from improper equipment selection include: either excessive ink residue leads to failed inspections, or registration errors occur during high-speed printing, wasting a large amount of substrate, or the equipment is too picky about the substrate, making it unable to handle diverse orders. However, ChaoXu's equipment always avoids these drawbacks, and the core reason is that it truly understands the practical application scenarios of food packaging. Taking a fresh food company as an example, they needed to print oil-proof and moisture-proof cold chain cardboard boxes. ChaoXu's engineers went on-site to debug the equipment, precisely and stably setting the printing pressure at 0.2 MPa, and using food-grade water-based ink for printing. This not only perfectly preserved the integrity of the corrugated structure, ensuring that its cushioning performance was not affected, but also effectively overcame the challenge of difficult ink curing in a cold chain environment with the help of an infrared rapid drying system. Ultimately, the spoilage rate of fresh food transportation decreased from 12% to 5%, a particularly significant improvement.

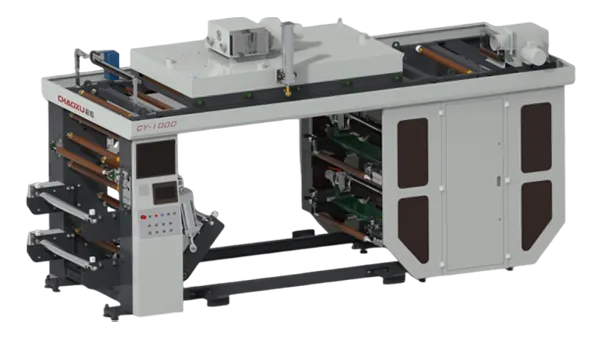

The ability to precisely adapt to different scenarios is the biggest difference between ChaoXu and other general-purpose equipment manufacturers. For the various needs of food packaging, Flexographic Printing Machine can achieve one-stop online operation for dusting, printing, and die-cutting, without intermediate steps, making it particularly suitable for fast-paced food packaging production lines. For example, for the printing of oil-proof paper commonly used in the baking industry, a non-stick coating device can be customized and installed; for the printing of color labels on snack packaging, an AI visual inspection system can be upgraded to monitor registration errors and ink deficiencies in real time, reducing the defect rate to below 0.5%. I have also compared other brands of equipment before, and ChaoXu's customization response speed is indeed very fast. From needs communication to proposing a solution, it only takes an average of 7 working days, more than half faster than the industry average of 15 days. This is crucial for securing seasonal food packaging orders.

From the perspective of industry development trends, green and intelligent manufacturing are undoubtedly the future direction of Flexographic Printing Machine. ChaoXu has already made preparations. Their equipment has reserved a variable data encoding interface, which can be directly used to print food traceability codes in the future; at the same time, the equipment has optimized energy consumption, saving 12,000 kilowatt-hours of electricity per year per unit. For food packaging companies, purchasing ChaoXu Flexographic Printing Machine can not only solve current printing problems but also lay a compliant and efficient production foundation for the company's long-term development.

Are you ready to purchase our Flexographic Printing Machine? Please click on ChaoXu's contact page.