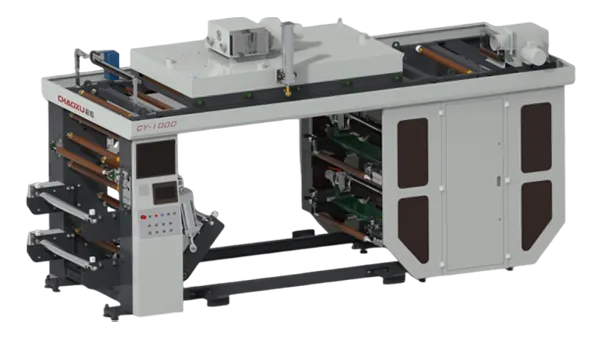

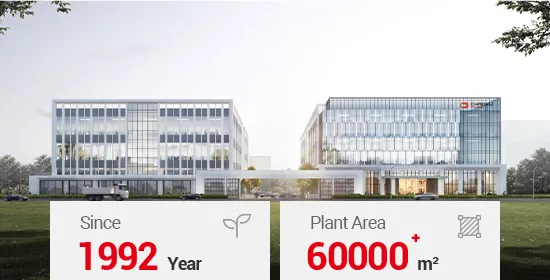

Chaoxu Flexographic Printing Press Series, built upon three decades of machinery manufacturing expertise, is engineered for the global packaging and printing industry. We offer a complete range from compact stack type to high-performance unit-type models, ideally suited for printing on plastic films, non-woven fabrics, woven bags, and various papers.

Leveraging full servo drive, intelligent closed-loop tension control, and an efficient multi-mode drying systems, Chaoxu presses guarantee exceptional printing accuracy, stable production efficiency, and broad material compatibility.