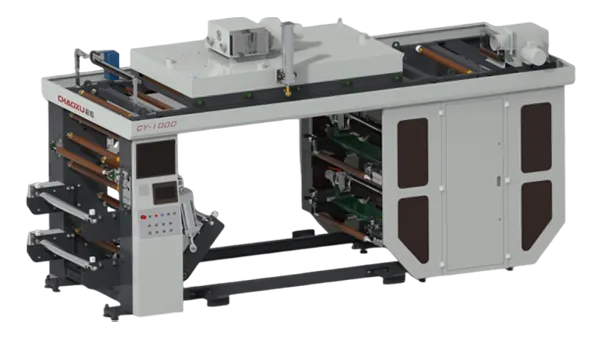

CX-FQ

High-Speed Slitting Machine

This high speed slitting machine is suitable for slitting roll materials such as BOPP,PET,CPP,CPE,PVC,Aluminum foil,Adhesive paper,Leather paper etc.

- 10-500m/min Slitting speed

- 600mm Max. Diameter of rewinding

- 800mm Max. Diameter of raw material