Düsseldorf, Germany – As the global plastics and rubber industry converges at K 2023, all eyes will be on innovators shaping the future of packaging. Among them, Chaoxu Machinery, a Chinese equipment manufacturer with three decades of expertise, is set to make a significant impact. The company will present its advanced series of full-servo flexographic printing presses and high-speed slitting machines, offering global customers reliable, high-precision, and cost-effective packaging solutions.

Where Precision Meets Speed: Redefining Intelligent Production

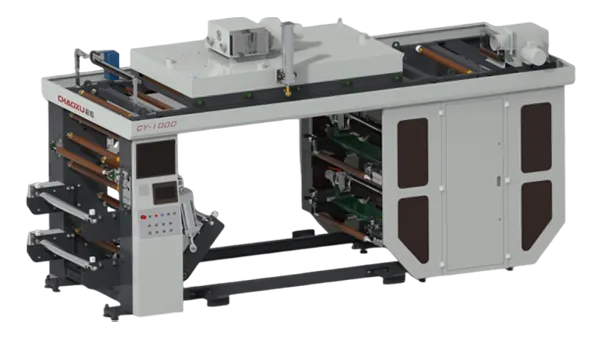

In packaging printing, the relentless pursuit of accuracy, speed, and stability is paramount. Chaoxu's exhibit centerpiece, the CX-JZ.D series unit-type full-servo flexographic press, embodies this philosophy. It achieves a remarkable register accuracy of ±0.1mm at production speeds of up to 200 meters per minute, effectively solving the industry challenge of maintaining print consistency on stretchable films at high velocities. Its closed-loop tension control system and real-time CCD register inspection act as an "intelligent eye and steady hand," ensuring vibrant colors and sharp, high-definition print quality throughout long production runs.

"We believe 'intelligence' in machinery is not about feature overload, but about leveraging stable and reliable technology to make production simpler and more efficient," stated a Chaoxu Technical Director. "By integrating servo systems and controllers from global leaders like Siemens and ABB, we guarantee long-term operational stability from the source. Furthermore, our mandatory 72-hour pre-delivery simulated production testing is our hardened commitment to every customer."

Green and Flexible: Answering the Global Call for Sustainable Packaging

In response to rising global environmental demands, Chaoxu's equipment provides a solid foundation for producing "green packaging." Their machines support both water-based and UV inks and can be configured with hot air, infrared, and UV drying systems, catering to a wide array of substrates. Whether for recyclable paper packaging or lightweight plastic films, Chaoxu empowers customers to meet sustainability goals without compromising on performance.

Moreover, the modular design of Chaoxu's equipment offers unparalleled flexibility. Customers can customize printing widths and the number of color units and seamlessly integrate inline processes like dust removal, corona treatment, die-cutting, and varnishing. This enables integrated "printing-to-post-press" production, significantly boosting overall efficiency and market responsiveness.

Beyond Hardware: Building Global Partnerships through Service

"Choosing Chaoxu means gaining a long-term, trustworthy partner," emphasized a Chaoxu International Business Manager. Supported by a 60,000 sqm modern production base in Wenzhou, China, Chaoxu maintains a professional team for installation, commissioning, and aftersales service, covering the entire equipment lifecycle from selection and training to ongoing technical support. Their 24/7 technical support center and efficient spare parts supply system ensure that customers, regardless of location, receive prompt assistance to maximize production continuity.