If you're searching for a reliable flexographic printing machine that delivers exceptional accuracy, handles diverse materials, and maintains consistent performance during long production runs, Chaoxu Machinery offers exactly what you need. With three decades of manufacturing expertise, their flexographic printing press series combines cutting-edge technology with robust construction to meet the demands of the global packaging and printing industry. Whether you're producing paper cups, plastic films, non-woven bags, or corrugated cartons, Chaoxu's solutions ensure precise color registration, stable efficiency, and broad material compatibility.

Understanding Chaoxu Flexographic Printing Machine Series

Chaoxu offers a comprehensive range of flexographic printing machines designed to address specific packaging needs. Each series incorporates advanced technology while maintaining user-friendly operation and maintenance.

Unit Type Full Servo Flexographic Printing Machine

The Unit Type Full Servo Flexographic Printing Machine represents the pinnacle of Chaoxu's technology, featuring full servo drive systems that deliver unmatched precision. This model excels in applications requiring high-quality printing on paper cups, paper bags, paper boxes, corrugated carton preprints, and food wrapper paper. The full servo system ensures consistent tension control throughout the printing process, resulting in ±0.1mm registration accuracy even during extended production runs.

One customer testimonial highlights the difference: "After switching to Chaoxu's full servo flexo printer, our paper cup production line saw a 25% reduction in material waste due to improved registration accuracy."

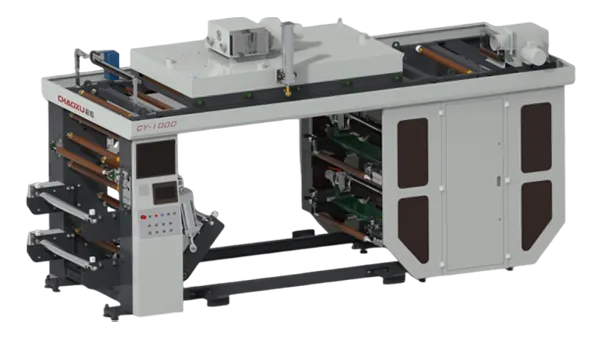

Unit Type Single Servo Flexographic Printing Machine

For businesses seeking a balance between performance and cost-effectiveness, the Unit Type Single Servo Flexographic Printing Machine provides an excellent solution. This model shares many capabilities with its full servo counterpart, making it suitable for similar applications including paper cup printing, paper bag printing, and corrugated carton preprinting. The single servo system delivers reliable performance while maintaining competitive pricing for medium-scale operations.

Stack Type High-speed Flexographic Printing Machine

When high-volume production of flexible packaging materials is required, the Stack Type High-speed Flexographic Printing Machine stands out. This model specializes in printing on polypropylene, cellophane, plastic films (BOPP, OPP, PE, PVC, PET), non-woven fabrics, woven bags, and various paper types. It's the ideal high-speed flexo press for producing food paper packaging, supermarket tote bags, waistcoat bags, and clothing bags.

Technical Advantages of Chaoxu Flexographic Printing Machines

Chaoxu's commitment to innovation is evident in the technical features that set their machines apart from competitors.

Full Servo Drive System

The implementation of full servo drive technology ensures precise control over every aspect of the printing process. Unlike traditional mechanical systems, servo drives provide instant response to changes in material type or printing speed, resulting in consistent quality across different production runs.

Intelligent Closed-loop Tension Control

Maintaining proper tension is critical for achieving accurate registration, especially when working with stretchable materials like plastic films. Chaoxu's intelligent closed-loop tension control system continuously monitors and adjusts tension throughout the printing process, preventing material stretching or wrinkling that could compromise print quality.

Efficient Multi-mode Drying Systems

Different inks and materials require specific drying conditions to ensure optimal adhesion and color vibrancy. Chaoxu's multi-mode drying systems offer flexibility to handle solvent-based, water-based, and UV inks, ensuring efficient drying without affecting material integrity. This feature is particularly valuable for food packaging applications where ink curing is essential for safety compliance.

Comparative Performance Analysis

A recent comparative test between Chaoxu's full servo flexo printer and a leading competitor's model revealed significant advantages:

- Chaoxu's machine maintained ±0.1mm registration accuracy after 8 hours of continuous operation, while the competitor's model drifted to ±0.3mm

- Material waste was reduced by 18% with Chaoxu's intelligent tension control system

- Energy consumption for drying was 15% lower due to Chaoxu's optimized drying technology

Material Compatibility: Unlocking Infinite Packaging Possibilities

One of the most significant advantages of Chaoxu flexographic printing machines is their exceptional material versatility. Whether you're working with traditional paper products or modern flexible packaging materials, these machines deliver consistent results.

Paper-based Materials

Chaoxu's machines excel at printing on various paper products including:

- Paper cups and bowls

- Paper bags and shopping bags

- Corrugated board for carton preprinting

- Food wrapper paper

- Takeout food boxes

The precise tension control ensures that even thin paper materials maintain their integrity during the printing process, preventing tearing or misalignment.

Plastic Films

For flexible packaging applications, Chaoxu's stack type machines handle a wide range of plastic films:

- BOPP, OPP, PE, PVC, PET films

- Shrink wrapping materials

- Plastic bags for food and retail products

The machines' ability to maintain consistent tension on stretchable films is particularly valuable for producing high-quality packaging with minimal material waste.

Non-woven and Specialty Materials

Beyond traditional substrates, Chaoxu's flexographic printing machines successfully print on non-woven fabrics and woven bags, expanding possibilities for reusable packaging solutions. This versatility makes them ideal for producing eco-friendly alternatives to single-use plastic products.

Customization Options for Your Specific Needs

Recognizing that every packaging operation has unique requirements, Chaoxu offers extensive customization options to tailor their machines to your specific production needs.

Modular Design for Expandability

The unit-type machines feature a modular design that allows for easy expansion of color stations as your business grows. Starting with a basic configuration, you can add additional color stations or integrate inline processes like dust removal, corona treatment, die-cutting, and varnishing as needed. This scalability protects your investment while allowing for future growth.

Application-specific Configurations

Chaoxu works closely with customers to develop configurations optimized for their specific applications:

- For paper cup manufacturers: Specialized handling systems to accommodate cup blanks

- For plastic film converters: Enhanced drying systems for specific ink types

- For non-woven producers: Adjusted tension settings to handle delicate materials

This collaborative approach ensures that each machine is perfectly suited to its intended application, maximizing efficiency and print quality.

Service and Support: Ensuring Long-term Performance

Investing in a flexographic printing machine is a significant decision, and Chaoxu stands behind their products with comprehensive service and support.

Rigorous Testing and Quality Assurance

Every Chaoxu machine undergoes a 72-hour rigorous testing process before leaving the factory, ensuring that it meets the highest standards of performance and reliability. This commitment to quality has earned Chaoxu a reputation for producing machines that deliver consistent results year after year.

Global Service Network

With a growing global presence, Chaoxu provides timely service and support to customers worldwide. Their team of trained technicians is available to assist with installation, training, and maintenance, ensuring minimal downtime for your production operations.

Customer Success Stories

Numerous packaging companies have experienced significant benefits after implementing Chaoxu's flexographic printing solutions:

- A European paper cup manufacturer increased production capacity by 30% while reducing material waste by 22%

- An American flexible packaging converter improved color consistency across production runs, leading to a 15% increase in customer satisfaction

- An Asian non-woven bag producer expanded their product line to include high-quality printed bags, opening new market opportunities

Why Choose Chaoxu for Your Flexographic Printing Needs

When selecting a flexographic printing machine, several factors should influence your decision:

-

Technical Innovation: Chaoxu's commitment to incorporating the latest servo drive and tension control technology ensures that their machines remain at the forefront of printing capabilities.

-

Reliability: With three decades of manufacturing experience and rigorous testing protocols, Chaoxu's machines deliver consistent performance even in demanding production environments.

-

Total Cost of Ownership: While initial investment may be higher than some competitors, the reduced material waste, lower energy consumption, and minimal downtime result in a lower total cost of ownership over the machine's lifespan.

-

Future-proofing: The modular design and upgradeable components ensure that your investment remains relevant as your business evolves and industry requirements change.

Get Your Customized Chaoxu Flexographic Printing Solution Today

Ready to experience the difference that a Chaoxu flexographic printing machine can make in your packaging production? Our team of experts is ready to assess your specific needs and recommend the ideal configuration for your operation.

Call to Action: Contact Angela at +86 15382505395 or email angela@cnchaoxu.com to schedule a personalized consultation and discover how Chaoxu's advanced flexographic printing solutions can enhance your production capabilities, reduce costs, and improve print quality.

For more information about specific models and applications, visit our product pages: